First published on Thursday, August 29, 2024

Last updated on Thursday, August 29, 2024

Jump to section

Safe Work Method Statements or SWMS are a lot more self-explanatory than they may appear.

A safe work method statement is a document that’s required before a workplace takes on any high-risk construction work.

The Occupational Health & Safety Regulations 2017 require all employers to prepare and have an accepted SWMS in operation before undertaking risky work. So, preparing this document is a legal obligation.

What’s in a safe work method statement?

The document must be created before the high-risk work is carried out. A business can either create one SWMS to cover a number of high-risk activities or create a separate statement for each activity.

Each statement should:

Identify the work that is to be undertaken

Outline the hazards and the risks associated with them

Describe the control measures put in place to manage risks

Describe how the aforementioned control measures will be rolled out, monitored, and reviewed

Be read and understood by every person using the document

When do you need a safe work method statement?

What is meant by high-risk construction work may vary depending on the particular state and territory you operate in.

For example, WorkSafe Victoria outlines 19 high-risk construction work activities while NSW Work Health and Safety Regulation 2017 details 18. For the most accurate and up-to-date information, it’s best to refer to the guidelines provided by the WHS regulator in your state or territory. Or you can use a health and safety advice line.

Having said that, here are some examples of high-risk construction work activities listed by Safe Work Australia.

Activities that:

Involve the risk of an individual falling further than 2 meters

Are carried out on a telecommunications tower

Involve the demolition of an element of a load-bearing structure

Involve the demolition of a structural element that relates to the physical integrity of the structure

Involve or may involve disturbing asbestos

Involve structural repair or alterations that require temporary support to prevent collapse

Are carried out in or near confined spaces

Are carried out in or near shafts or trenches deeper than 1.5 metres or a tunnel

Involve using explosives

Are carried out in or near pressurised gas mains or piping

Are carried out in or near chemical, fuel, and refrigerant lines

Are carried out in or near energised electrical installations or services

Are carried out in areas that may have a contaminated or flammable atmosphere

Involve tilt-up or precast concrete

Are carried out on, in, or adjacent to roads, railways, shipping lanes, or any other traffic corridors used by traffic or pedestrians

Are carried out in a workplace area where there is movement of powered mobile plant

Are carried out in areas with artificially extreme temperatures

Are carried out in or near water or other liquid that may carry drowning risks

Involve diving

Are all considered high-risk work.

Who is responsible for SWMS?

There are many people who should be actively involved in the process of creating SWMS.

An employer of the employees undertaking the high-risk work will need to create the document.

Self-employed people and contractors will need to create this document for themselves.

In a labour hire arrangement, the host employer of the employees undertaking the high-risk work will need to create the SWMS.

How to prepare SWMS

Gather the team involved in the high-risk activity including employees, health & safety representatives, and supervisors.

Review the proposed activities and take into consideration any site-specific factors that may affect the progress of these activities.

Include a comprehensive list of all the high-risk work identified and their associated hazards and risks.

Review, assess, and update the document as needed if any developments take place like weather changes.

Make sure your SWMS is read, understood, and accepted by everyone involved in the high-risk work.

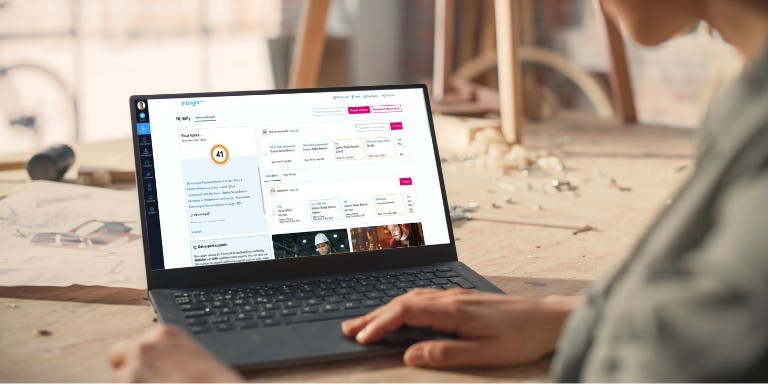

Health & safety software can help you share and store SWMS in one central location for easy access and reference.

How to streamline your SWMS process

When it comes to workplace health & safety, the primary goal is to eliminate risk or—if that’s not possible—manage and lower risks as far as possible.

Consistent, proactive management of your work health & safety tasks and risk management procedures can help you achieve that goal.

That’s why BrightSafe is designed to cover your work health & safety processes from end to end. From instant hazard and near miss reporting to an SWMS Navigator that guides you through every step in the critical process.

Not yet a BrightSafe customer? Book a demo to see all the ways it can transform how you manage your work health & safety.